Tornar o tratamento de COVs mais seguro, eficiente e econômico

Tornar o tratamento de COVs mais seguro, eficiente e econômico

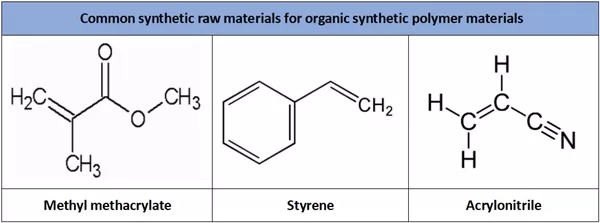

Organic synthetic polymer material is a kind of polymer material with certain functional properties, which is produced by the polymerization of unsaturated organic molecules with double bond structure under initiating conditions. Due to its good strength performance, excellent chemical corrosion resistance and lightweight, it has been widely used in all aspects of our production and life. However, in the process of chemical synthesis and production of organic synthetic polymer materials, the commonly used raw materials such as acrylic, acrylonitrile, styrene and other organic monomer molecules have certain volatility. Even if condensation reflux process is adopted for intercept recycling, some VOCs will inevitably escape to the waste gas. If not effectively treated, the air will be polluted and valuable resources will be wasted.

At present, the feasible treatment methods for this problem are mainly the combustion method and the adsorption method. The combustion process achieves the target by forced burning volatile gases. The heat generated by combustion can be recovered, but organic molecules such as acrylates and styrene have a low heat value but with a high value for product itself. If they are simply processed by combustion, it is not economical. The adsorption process uses core adsorption materials to effectively adsorb and intercept VOCs molecules to achieve the purpose of waste gas treatment . However, traditional activated carbon, molecular sieve and other adsorption materials, due to the lack of purity in the surface and pore structure (containing impurities such as metals), will cause the adsorbed unsaturated organic molecules to rapidly polymerize in the pores of the adsorbing material to form polymers and block the pores, which affects the subsequent adsorption processing performance, and the polymers formed in the pores are difficult to effectively remove, resulting in the failure of periodical use of adsorption materials, as well as short life and high processing costs. Moreover, the polymerization reaction of organic molecules is an exothermic reaction, once the adsorbed unsaturated organic molecules polymerize in the pores of the adsorption material, the instantaneous heat energy generated in the limited space will also bring certain safety hazards (especially for activated carbon).

The

special resin seplite

® CT-10

for

VOCs treatment

developed and produced by

Sunresin

, adopts a special synthesis process and production control, so that it has a higher active specific surface area, good mechanical strength and thermal stability, with better pore structure and higher purity. In the

adsorption

treatment of unsaturated VOCs

, the good purity and inert environment inside the

seplite

® CT-10 resin

estrutura pode efetivamente evitar a ocorrência da polimerização de VOCs adsorvidos, o que elimina fundamentalmente o problema de cura molecular e exotermia causada pela polimerização de moléculas orgânicas insaturadas, evita danos ao material de adsorção de resina e reduz significativamente os riscos potenciais de segurança causados pela polimerização exotermia. A resina saturada adsorvida pode ser efetivamente regenerada por purga de vapor de alta pressão, e as moléculas orgânicas insaturadas regeneradas podem ser recicladas de volta ao processo de produção, reduzindo os custos. Após o tratamento de resfriamento simples, a resina após a regeneração a vapor pode entrar no próximo ciclo de adsorção. Com o ciclo periódico, a resina terá longa vida útil e menor custo operacional.

Seplite

® Resina especial CT-10

Equipamentos para tratamento de COVs

Seplite

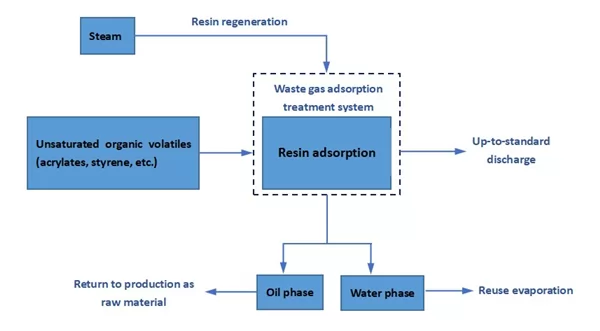

® Rota de processamento da resina CT-10 para tratamento de COVs:

Visando os VOCs insaturados produzidos na síntese química de materiais de polímeros sintéticos orgânicos, a Sunresin tem materiais de adsorção de núcleo recicláveis de alto desempenho e soluções de processo de suporte correspondentes, com as quais o material de adsorção de núcleo e o processo podem ser otimizados com base nas condições de trabalho específicas do usuário para criar mais valores para os usuários enquanto resolve os problemas ambientais. Nossa profissionalidade certamente atenderá às suas necessidades!